Make things different- make things better

Keeping your machine in tip-top condition

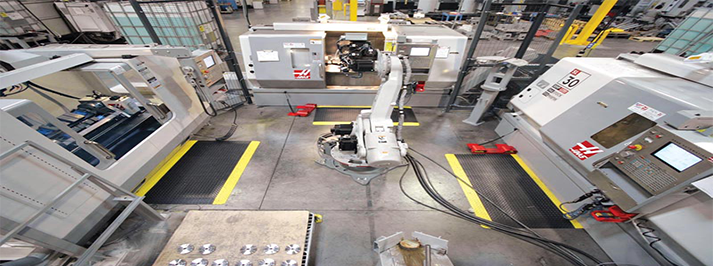

Machining Solutions and Job Works

Our range of support for CNC machine tools is second to none and includes -: CNC Lathes & Turning Centres, Vertical Turning Lathes, CNC Machining Centres (Vertical, Horizontal), Horizontal Boring Machines, Multi-axis Mill-Turn Centres, 5-Axis Machining Centres, Double Column Milling Machines, Metal Forming Fabrication Machines Laser, Waterjet, Punching, Bending and Rolling.

We also provide customers with a range of world-class after-sales services and support. These include:

If you’re looking for a new CNC machine support now or in the future we believe that a Gulf Adonis solution cannot be beaten on price, performance or reliability.